ВОЛНИСТОСТЬ ПОВЕРХНОСТИ ПРИ ОБКАТЫВАНИИ

advertisement

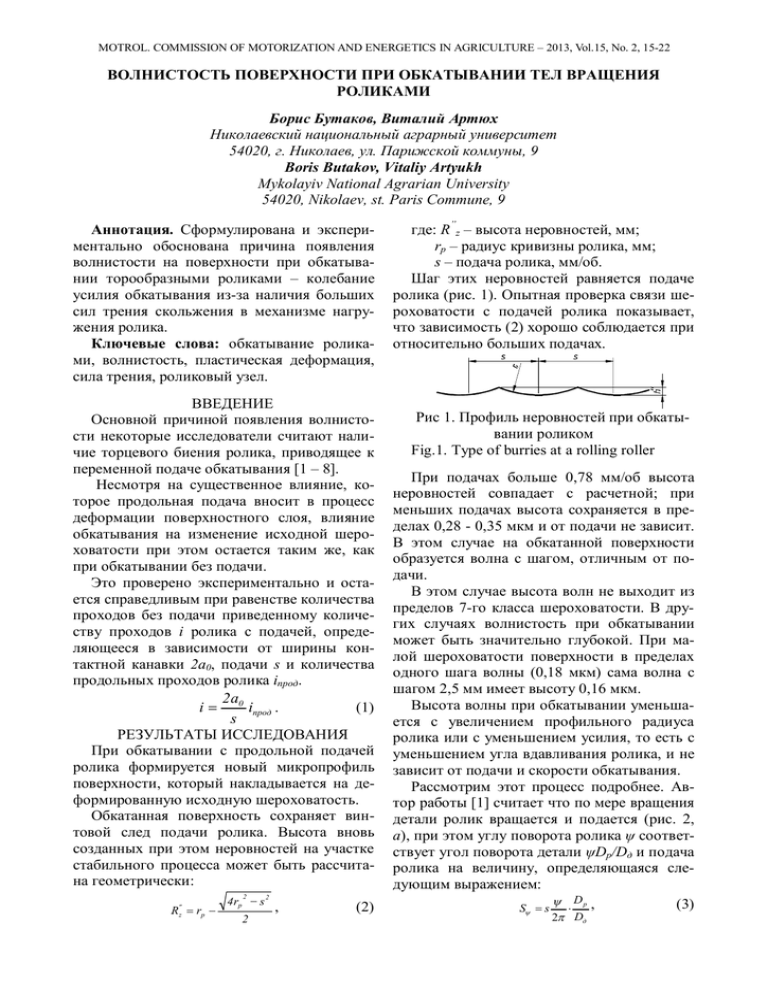

MOTROL. COMMISSION OF MOTORIZATION AND ENERGETICS IN AGRICULTURE – 2013, Vol.15, No. 2, 15-22 , 54020, . , . ,9 Boris Butakov, Vitaliy Artyukh Mykolayiv National Agrarian University 54020, Nikolaev, st. Paris Commune, 9 . : R”z – r – s– - , ; , , ; . – ( . 1). , . (2) : , , , , . . 1. - - Fig.1. Type of burries at a rolling roller , [1 – 8]. , 0,78 - ; , . 0,28 - 0,35 , , . - i 0, s i 2 a0 i s . 7- - , - . . - . (0,18 . 2,5 ) 0,16 - . - (1) , , . , - . . - [1] - . ( ), . 2, - D /D - , : : R"z r 4r 2 2 s2 , (2) S s Dp 2 D , (3) 16 , :s– , . - s s s. (4) : s 2 sin cos D D 2 0 2 D D 0 sin D . (5) D sin sin D /D , , , , 0 ( s . 2, ). s , . . , . 2. : - – , s=f( ): – , , , – , , ,– s' - D D sin sin D D 0 0 . (6) : , - D D 0 Fig. 2. Washboarding surface at a rolling-off: and is a change of serve at to axial beating of roller, is an involute of surface of billow, obkatannogo a roller, not having the axial beating, in – an involute of surface of billow, obkatannogo a roller with the osevim beating at the multiple diameters of detail and roller, gramme, is an involute of surface of billow, obkatannogo a roller at the not multiple diameters of detail and roller n, : n = 0; 1; 2; 3; … : n D D 0 . (7) - (5), : max smin sin (5) - D . D (8) , s . . , , , ( . 2, ). , , . - , , . , - - – . 2, ). . - - - . : – ( . 2, ) - 17 , , - , . . , - , . - . , , , - , . , . - , . ( . 3) 25’-30’ , 40’-1° 1° 30’ [1, 2, 9]. .1. , . ( - . 3, ). . - /s - , , . - . , - D . GHI , EFG . 20’-30’ D . [10 – 15]. , , , - /s. . . 3. , - S: – , . ; – Fig. 3. Chart of successive deformation of surface of details at a rolling a roobraznym roller with the longitudinal serve of S: and – at a normal process; – the process of deformation was not stabilized . 3, . [1] : L : – 1,27 P , HB , . (9) 18 , 1 [1, 16 – 19] Table 1. Geometrical sizes of inlet cavity at the beginning of rolling area [1, 16 – 19] , D, D, , r, S, t, - - 5 20 5 50 34 54 16 5,5 54 5,5 3 84 114 50 131 115 50 180 300 105 196 235 235 475 105 10 12 10 270 500 105 10 15000 0,61 0,43 0,3 1,04 0,3 0,3 0,04 0,08 0,18 0,02 0,18 0,3 60000 0,5 0,7 0,5 0,45 0,5 0,4 6000 8400 59500 40 (200 ) 12 12 11,2 9,3 9,5 12 10,8 10 11,5 20 22 18 22 22 18 100 - “ ” , - . - , . 4 [20]. 230 ( 80 , , 40 < Rz < – . , , . , , , ; - . 4. - . - Fig. 4 Device for rolling of details by a toroobraznim roller with stabilization of effort of rolling : 7 19 12, 13 4, 5 11. - 8 6 7 - . 6 9 , 10 . 5. . 6. : ; - – – ; z – ; – . 5. - Fig. 5 General view of device for the rolling of details by a toroobraznym roller with stabilizing of working effort of rolling 0,745 ( (f ) - . ) : =j ×f , : j . – , j (10) = 0,472 - - Fig. 6 onstituents of effort of rolling on a detail: is tangent effort of woobling of roller; is nominal effort of screwing of roller to the detail; z is effort of serve; is loading from a back grandmother in axial direction : , =5 , = 0,15 : 5 : 1,5. : , : - z ; z ( ) . , , < 0,03 , . : = 60/38 = f = 0,745 f , : 60 38 0,472 = 0,45, 60 / 38 = (11) - f = 0,05 ÷ 0,1, f = 0,003÷ 0,008, - . .6 - .7 . , - - , ; , , . , - . - . , 20 , . .7. Fig. 4 Oscillogram of constituents of effort of rolling-off of R during setting of roller knot on supports of sliding . 8. Sw Fig. 8. Chart of computation of step of the Sw wave at rolling by rollers Sw , R = 0,08 – 0,32 Rz = 80 - 160 , D /D . ( . 8). , , . - Sw, S , . , . , . 9 . 1 1 : Sw = D S / (D N – D ), : N = D /D + 1 ( D /D ). , , 20, 140 , D = 117 = ,D = (12) - ) 5 , S = 0.2 60 , , . ( . - . 9. .) Sw = 3,9 Sw, - , (12). Sw. ( ), . - 21 9. 20: – Rz =100 – – 0,16 ; (R = 0,08 - ); – Fig. 9. Profilogrammy of surface of billow from steel 20: and – to the rolling-off of Rz =100 mk; á – after a rolling-off during setting of roller knot on bearings of woobling (Ra = 0,08 – 0,16 mkm); 3 – after a rolling-off during setting of roller knot on supports , ( 5°) - . 1. Braslavskij V. 1975. Tehnologija obkatki krupnyh detalej rolikami / V. M. Braslavskij. 2-e izd. – M.: Mashinostroenie. – 160. 2. Azarevich G. 1963. Chistovaja obra-botka cilindricheskih poverhnostej plasti-cheskim deformirovaniem / G. Azarevich G. Bershtejn - M.: ONTI NII Traktorsel'-hozmasha. - 43. 3. Braslavskij V. 1989. Obkatka deta-lej rolikami kak sredstvo povyshenija izno-sostojkosti / V. Braslavskij, V. Topych-kanov. Pr-vo krupnyh mashin, NIITJaZhMASh Uralmashzczoda. — Vyp. XIX. — 136 — 144. 4. Braslavskij V. 1975. Tehnologija ob-katki krupnyh detalej rolikami / Braslavskij V. M. - M.: Mashinostroenie. - 160. 5. Odincov L. 1987. Uprochnenie i ot-delka detalej poverhtnosnym plasticheskim deformirovaniem / L. Odincov – M.: Mashinostroenie. – 160. 6. Ryzhov Je. 1971. Povyshenie iznoso-stojkosti soedinenij tehnologicheskimi me-todami obrabotki/ Ryzhov Je., Braslavskij V., Topychkanov V. Nauch. – teh. sb. Brjan. in – ta transport. Mashinostroenija. – 2. — 47 — 51. 7. Ryzhov Je. 1972. Vlijanie usilija obkatyvanija na geometriju nerovnostej / Ryzhov Je., Braslavskij V., Topychkanov V. Nauch. – teh. sb. Brjan. in – ta transport. Ma-shinostroenija. – 2. — 47 — 51 8. Ryzhov Je. 1979. Tehnologicheskoe obespechenie jekspluatacionnyh svojstv deta-lej mashin / Ryzhov Je., Suslov A., Fedorov V. – L.: Mashinostroenie. – 176. 9. Braslavskij V. 1985. Povyshenie iznosostojkosti vintovyh par obkatyvaniem rolikami / V. Braslavskij, B. Butakov, J. Shilkov. Tehnologija, organizacija i me-hanizacija mehanosborochnogo proizvodstva. — M.: NIIformTJaZhMASh, — 15 — 17. 10. Shnejder J. 1982. Jekspluatacion-nye svojstva detalej s reguljarnym mikro-rel'efom / Shnejder J. – L.: Mashino-stroenie. – 248. 11. Konovalov E. 1968. Chistovaja i uprochnjajushhaja rotacionnaja obrabotka poverhnostej/ Konovalov E., Sidorenko V. – Minsk: Vyshejsh. shk., – 364. 12. Kudrjavcev I. 1984. Novye sposoby poverhnostnogo plasticheskogo deformirova-nija / I. Kudrjavcev, R. Grudskaja. Mashi-nostroitel', 7, 28-29. 13. Fridman J. 1987. Mehanicheskie svojstva metallov / J. Fridman — M.: Mashinostroenie. — 556. 14. Popov . 2010. Novaja teorija kontakt-noj prochnosti uprugo szhatyh tel / Motrol, Motoryzacja I energetyka rolnictwa. – Lublin Tom12A. - 223 – 232. 15. Mamarin V. 2010Vlijanija oval'nosti poverhnosti shipa na harakteristiki pro-filirovannyh podshipnikov / Motrol, Motoryzacja I energetyka rolnictwa. – Lublin. - Tom12A. 31 – 36. 16. Babej J. 1995. Poverhnostnoe up-rochnenie metallov/ J. Babej, B. Butakov, V. Sysoev - K.: Naukova dumka. – 256. 22 , 17. Papshev D. 1983. Otdelochnouprochnjajushhaja obrabotka poverhnostnym plasticheskim deformirovaniem / D. Papshev – M.: Mashinostroenie. – 152. 18. Kudrjavcev I. 1951. Vnutrennie na-prjazhenija kak rezerv prochnosti v mashino-stroenii / Kudrjavcev I. – M.: Mashgiz. – 278. 19. Shkol'nik L., Shahov V. 1964. Tehnologija i prisposoblenija dlja uprochne-nija i otdelki detalej nakatyvaniem. – M.: Mashinostroenie. – 184. 20. Pat. 71119 Ukra na, MPK V24V 39/00. Pristr j dlja zm cnjujuchogo ta chistovogo obkatuvannja poverhon' t l obertannja z stab zac ju robochogo zusillja / B. Butakov, V. Artjuh; zajavnik vlasnik Butakov B. – u201112463; zajavl. 24.10.2011; opubl. 10.07.2012, Bjul. 13. WAVINESS OF SURFACE AT ROLLING-OFF OF BODIES OF ROTATION ROLLERS Summary. Formulated and reason appearance of waviness is experimentally grounded at a rolling toroobraznymi rollers is oscillation of effort of rolling from the presence of large forces of sliding friction in the mechanism of loading of roller. Key words: rolling, waviness, flowage, force of friction, roller knot, rollers